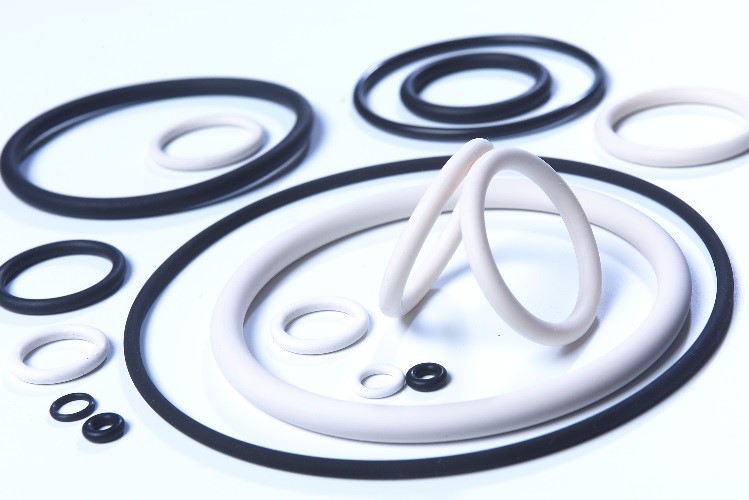

What is an O-Ring Seal? An O-ring seal is used to prevent the loss of a fluid or gas. O-ring is a torus, or doughnut-shaped ring, generally moulded from an elastomer, although O-rings are also made from PTFE. O-rings can form a static or dynamic seal. A static o-ring seal is used for containing a pressure or maintaining a vacuum. Dynamic o-ring seals can be reciprocating or rotating. An o-ring, when installed, compresses and deforms slightly into the free space within the groove to form a proper seal.O-rings are used primarily for sealing.

What is an O-Ring Seal? An O-ring seal is used to prevent the loss of a fluid or gas. O-ring is a torus, or doughnut-shaped ring, generally moulded from an elastomer, although O-rings are also made from PTFE. O-rings can form a static or dynamic seal. A static o-ring seal is used for containing a pressure or maintaining a vacuum. Dynamic o-ring seals can be reciprocating or rotating. An o-ring, when installed, compresses and deforms slightly into the free space within the groove to form a proper seal.O-rings are used primarily for sealing.

O-rings are one of the most common seals used in machine design. And o-ring is measured by its inner and outer diameters. O-rings are described by material composition and hardness. O-rings are typically available in standard sizes per industry standards. O-rings are available in both metric and inch sizes. O-ring selection is based on chemical compatibility, application temperature, sealing pressure, lubrication requirements, quality, quantity and cost.

Advantages of O-Rings

• They seal over a wide range of pressure, temperature and tolerance.

• Ease of service, no smearing or retightening.

• No critical torque on tightening, therefore unlikely to cause structural damage.

• O-rings normally require very little room and are light in weight.

• In many cases an O-ring can be reused, an advantage over non-elastic flat seals and crush-type gaskets.

• The duration of life in the correct application corresponds to the normal aging period of the O-ring material.

• O-ring failure is normally gradual and easily identified.

• Where differing amounts of compression effect the seal function (as with flat gaskets), an O-ring is not effected because metal to metal contact is generally allowed for.

• They are cost-effective